Choosing the right asphalt mixing plant is a critical decision for contractors and investors in the construction industry. Whether you plan to produce asphalt for your own projects or enter the commercial asphalt sales market, understanding the price range and factors affecting costs can help you make a smart investment. This article explores the key differences in pricing between asphalt mix plant for self-use and those designed for commercial sales, giving you practical insights from the customer’s perspective.

Why Price Matters When Selecting an Asphalt Mixing Plant

Price often ranks among the top concerns for buyers. However, the decision should not focus solely on the initial cost. Instead, it should reflect your production needs, project scale, and long-term business goals. Asphalt mixing plants come in different configurations and capacities, affecting their price and performance. Recognizing these differences ensures you invest in equipment that fits your operational demands without overspending.

Next, let’s examine how the intended use—self-use or commercial sales—shapes the asphalt plant price range and plant features.

Price Range for Asphalt Mixing Plants Intended for Self-Use

Asphalt plants for self-use primarily serve contractors who produce asphalt for their own road construction, paving, or maintenance projects. These plants typically have moderate capacities, which balance efficiency and cost-effectiveness. The price range for self-use plants usually falls between $50,000 and $250,000, depending on capacity and configuration.

Factors Affecting Price in Self-Use Plants

- Capacity: Plants with output around 20–80 tons per hour suit small to medium-sized projects, lowering investment costs.

- Automation Level: Semi-automatic systems reduce upfront price while providing reliable operation.

- Mobility: Mobile or modular plants add flexibility but may cost more initially.

- Auxiliary Equipment: Basic control systems and fewer accessories reduce costs.

These features ensure contractors can produce quality asphalt on-site, avoid high transportation fees, and maintain control over project schedules. Because self-use plants usually produce less volume, buyers prioritize affordability and ease of operation.

Price Range for Asphalt Mixing Plants Designed for Commercial Asphalt Sales

In contrast, commercial asphalt producers require plants with higher capacities and advanced features to meet large-scale demands and ensure consistent product quality. Such plants command a higher price range, typically from $200,000 to over $1 million, depending on capacity and technological sophistication.

Key Price Drivers in Commercial Plants

- High Production Capacity: Plants with output exceeding 80 tons per hour accommodate large contracts and ongoing supply.

- Advanced Automation: Full automation enhances efficiency, reduces labor costs, and improves product consistency.

- Environmental Controls: Dust collectors and emission-reducing technology add to the upfront investment but meet regulations and customer expectations.

- Customization and Integration: Options such as storage silos, batching systems, and conveyor belts increase flexibility and cost.

Commercial asphalt sales require reliable, continuous production with minimal downtime. Therefore, buyers often invest more upfront to gain operational advantages and ensure competitiveness in the market.

Comparing the Two: What Should You Consider?

Both self-use and commercial plants have their unique advantages and cost structures. Understanding your project goals, production volume, and budget will guide your choice. If your projects are limited in size or location, a smaller self-use plant offers cost savings and easier management. Conversely, if you plan to supply asphalt regularly to other contractors or businesses, a commercial-grade plant provides scalability and enhanced features that justify the higher price.

Moreover, consider maintenance costs, energy consumption, and spare parts availability. Sometimes a slightly higher initial investment leads to lower overall expenses due to efficiency and durability.

Final Thoughts: Making the Right Asphalt Plant Investment

Choosing an asphalt mixing plant is more than a price comparison. It requires balancing your specific needs with the plant’s capacity, features, and long-term benefits. Both self-use and commercial asphalt plants serve different customer segments with distinct expectations and price ranges.

To make an informed decision, evaluate your current and future project demands carefully. Reach out to trusted suppliers who can recommend models suited to your goals, provide transparent pricing, and offer reliable after-sales support.

Why Choose Us for Your Asphalt Mixing Plant?

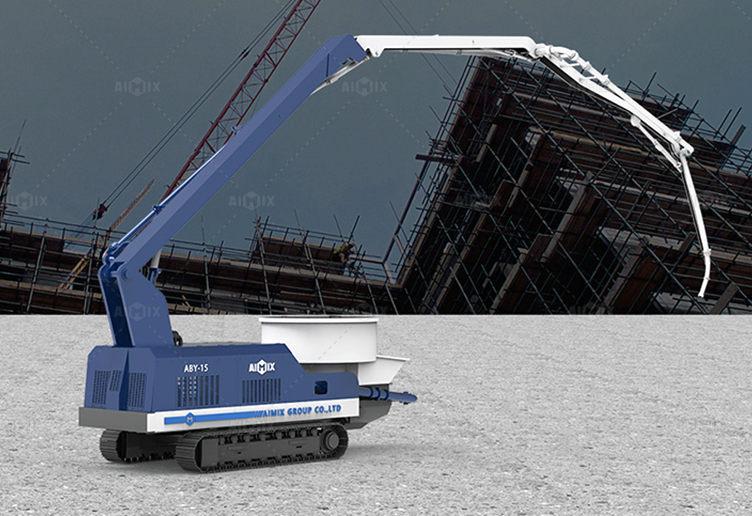

At AIMIX, we specialize in offering asphalt mixing plants tailored to your exact requirements. Whether you aim to produce asphalt for your own construction projects or establish a commercial asphalt sales business, we provide reliable, efficient, and cost-effective solutions. Our expert team guides you from selection to installation, ensuring a smooth operation and long-term success.

Contact us today to discuss your asphalt mixing needs and get a personalized quote. Invest smart, build better, and grow your business with confidence. Get to know the overall asphalt plant cost at right!