Choosing the right asphalt plant is crucial for road maintenance companies, especially when dealing with road patching projects. If you are considering using a 20-40 TPH mobile asphalt mixing plant for sale for projects that require less than 200 tons of asphalt per day, it is important to evaluate whether this plant capacity matches your daily production needs, project efficiency, and budget. In this article, we will explore this question from practical and industry-based perspectives to help you make an informed decision.

Understanding Mobile Asphalt Plant Capacities

Mobile asphalt plants with 20-40 TPH capacities are popular in road maintenance and small to medium road projects. These plants are designed to produce asphalt continuously, offering flexibility and quick relocation from one job site to another.

Typically, a 20 TPH portable asphalt plant for sale can produce around 160 tons of asphalt in 8 hours, while a 40 TPH plant can produce up to 320 tons in the same period. This output range perfectly matches road patching projects with daily asphalt requirements below 200 tons. However, understanding the real production needs is key before deciding.

Balancing Daily Demand and Plant Output

When your project consumes less than 200 tons of asphalt per day, choosing a plant that can comfortably meet or slightly exceed this volume is ideal. A 20-40 TPH mobile asphalt plant allows you to manage the production without the risk of overcapacity or equipment underuse. This balance not only reduces initial investment but also saves fuel, minimizes waste, and improves operational efficiency.

Besides, using an asphalt mixing plant that matches the project scale can lead to better quality control and more consistent asphalt supply throughout the day.

Why Mobile Asphalt Plants Are Ideal for Road Patching

Compared to stationary plants, mobile asphalt plants offer specific advantages that make them well-suited for road patching works. Let's take a closer look at these benefits.

Easy Relocation for Scattered Job Sites

Road patching projects often cover various sections across different areas. With a mobile asphalt plant, you can move the equipment quickly to the next site without long setup times. This mobility reduces transportation costs and shortens downtime between projects.

Quick Installation and Startup

Mobile asphalt plants usually require minimal foundation work and can be installed within a few days. This fast setup helps you respond quickly to urgent road repair needs. Rapid startup also means you can produce asphalt on demand without waiting for external suppliers.

On-Site Asphalt Supply Improves Efficiency

Having your own asphalt supply on-site improves work continuity. You can control the asphalt mix quality and production speed according to your repair schedule. This flexibility can help prevent delays and increase project efficiency.

How to Select the Right Mobile Asphalt Plant Capacity

Choosing between a 20 TPH or 40 TPH mobile asphalt plant depends on several factors, including your daily asphalt demand, project frequency, and site conditions.

Evaluate Daily Asphalt Requirements

If your daily consumption consistently stays around 100-150 tons, a 20 TPH asphalt mixing plant mini is usually sufficient. However, if you have occasional peaks that may reach close to 200 tons, a 40 TPH plant will provide extra production flexibility and avoid schedule pressure.

Consider Site Mobility and Transportation

Smaller capacity plants are generally lighter and easier to move. If your road patching sites change frequently and are spread over a wide area, a 20 TPH mobile plant may offer better mobility. On the other hand, if you need higher production without moving the plant frequently, the 40 TPH model could be a better option.

Think About Fuel Efficiency and Maintenance

A plant with the right capacity not only improves fuel efficiency but also reduces maintenance costs. Over-sizing the plant could result in unnecessary fuel consumption and higher operational expenses. Matching your plant size to your real demand keeps your cost structure lean and manageable.

Is a 20-40 TPH Mobile Asphalt Plant the Right Choice?

Based on practical construction scenarios, a 20-40 TPH mobile asphalt plant is generally well-suited for road patching projects with less than 200 tons of asphalt per day. It provides the right balance between mobility, capacity, and efficiency. You can optimize your operation, reduce waiting time for asphalt delivery, and improve project response speed.

However, it is essential to carefully assess your specific project conditions. If you expect consistent future growth or plan to take on larger contracts, considering a slightly higher capacity may offer more long-term flexibility.

Choose a Reliable Mobile Asphalt Plant Supplier

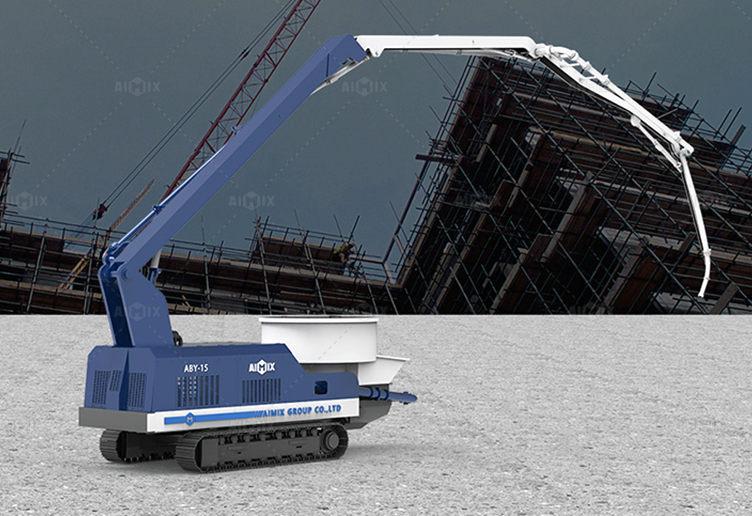

At AIMIX, we provide a wide range of mobile asphalt plants with proven performance in road patching and maintenance projects. Our mobile asphalt plants are easy to install, efficient, and designed with user-friendly controls to simplify your operation. We also offer local service teams in Indonesia to support your equipment throughout its lifecycle.

If you are looking for the right mobile asphalt plant for your road patching projects, contact us today. We are ready to help you find the best solution that matches your project needs and budget.