If you’re in the construction business and looking for an efficient, cost-effective solution for producing concrete on-site, a mini concrete batching plant is the perfect investment. These compact and powerful plants offer high performance while requiring minimal space, making them ideal for small to medium-scale projects.

For businesses that need flexibility, a portable concrete batching plant is an excellent option, allowing easy transportation and quick setup at multiple job sites. In this article, we’ll discuss the benefits of mini concrete batching plant, how they compare to portable models, and what to consider when making a purchase.

Why Choose a Mini Concrete Batching Plant?

A mini concrete batching plant is designed for small-scale operations that require consistent and high-quality concrete production. Unlike large stationary plants, mini batching plants are compact, easy to install, and require lower operational costs.

Key Benefits:

Space-Saving & Compact Design

- Requires minimal space for installation, perfect for urban construction sites.

Cost-Effective Solution

- Lower initial investment compared to larger plants, making it ideal for startups and small contractors.

Efficient Concrete Production

- Despite its size, it ensures consistent concrete mixing with high precision.

Easy to Operate & Maintain

- User-friendly control systems simplify operation, reducing labor costs.

Quick Installation & Mobility

- Some models come with wheels, allowing easy relocation to different sites.

Mini vs. Portable Concrete Batching Plant: Which One to Choose?

Both mini concrete batching plants and portable concrete batching plants offer efficient concrete production, but they serve slightly different purposes.

| Feature | Mini Concrete Batching Plant | Portable Concrete Batching Plant |

|---|---|---|

| Mobility | Generally stationary but compact | Fully mobile, can be relocated easily |

| Installation Time | Quick setup but requires a foundation | No foundation needed, faster setup |

| Production Capacity | Suitable for small to medium projects | Ideal for temporary or multi-site projects |

| Cost | More affordable | Slightly higher due to mobility features |

| Best for | Contractors with fixed projects | Construction companies with multiple job sites |

When to Choose a Portable Concrete Batching Plant?

If your projects require frequent relocation, investing in a portable concrete batching plant can save time and transportation costs. These plants are equipped with wheels and can be towed to different job sites, making them ideal for road construction, bridge projects, and remote site operations.

Factors to Consider Before Buying a Mini Concrete Batching Plant

Before purchasing a mini concrete batching plant, it’s essential to evaluate key factors to ensure you select the best model for your needs.

1. Production Capacity

- Choose a plant that meets your daily concrete demand. Mini plants typically range from 10m³/h to 50m³/h.

2. Mobility Requirements

- If you need frequent relocation, opt for a portable concrete batching plant.

3. Automation & Control System

- Advanced plants come with PLC control systems, allowing precise concrete mixing with minimal manual operation.

4. Mixer Type

- Twin-shaft mixers provide better efficiency for continuous production, while drum mixers are more budget-friendly.

5. Quality of Components

- Ensure the plant includes durable materials, high-quality conveyors, and reliable weighing systems.

6. After-Sales Support & Spare Parts Availability

- Reliable manufacturers offer warranties, training, and local service centers for quick maintenance.

How to Find the Best Mini Concrete Batching Plant for Sale?

Finding a high-quality mini concrete batching plant at a competitive price requires research and comparison.

Where to Buy?

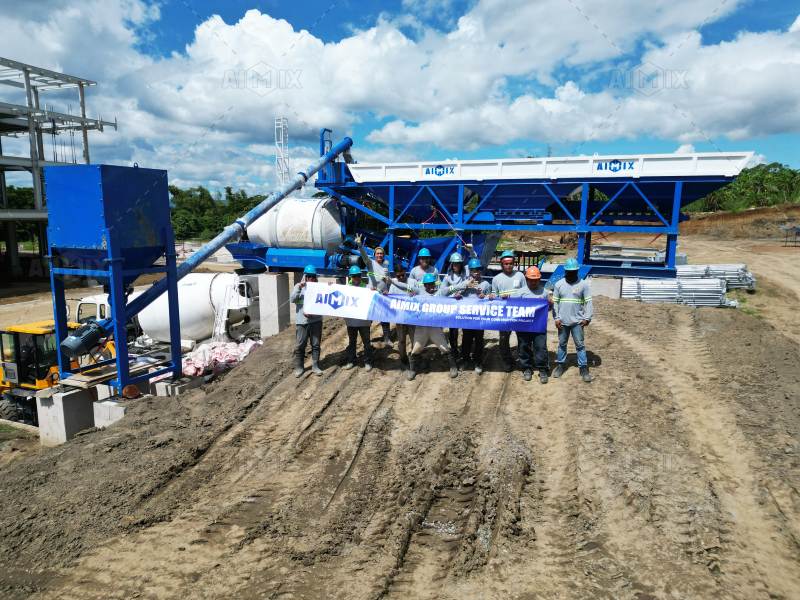

- Direct from Manufacturer: Brands like Aimix offer factory-direct pricing with customization options.

- Authorized Dealers: Check local suppliers for quick delivery and after-sales service.

- Online Marketplaces: Websites like Alibaba, Made-in-China, and Tradekey list various batching plants for sale.

Price Considerations

- The cost of a mini concrete batching plant varies from $10,000 to $50,000, depending on size, automation, and features.

- A portable concrete batching plant may cost slightly more due to its mobility functions.

Comparing Different Models

Before purchasing, compare different models based on:

Output capacity (m³/h)

Mixer type

Power consumption

Mobility options

Warranty & after-sales service

Conclusion

Investing in a mini concrete batching plant is a game-changer for small and medium-scale contractors. Whether you need a stationary mini batching plant or a portable concrete batching plant for on-the-go projects, choosing the right model can increase efficiency and reduce costs.

If you’re looking for fast delivery, high performance, and cost-effective pricing, explore trusted suppliers like Aimix to get the best deals today!